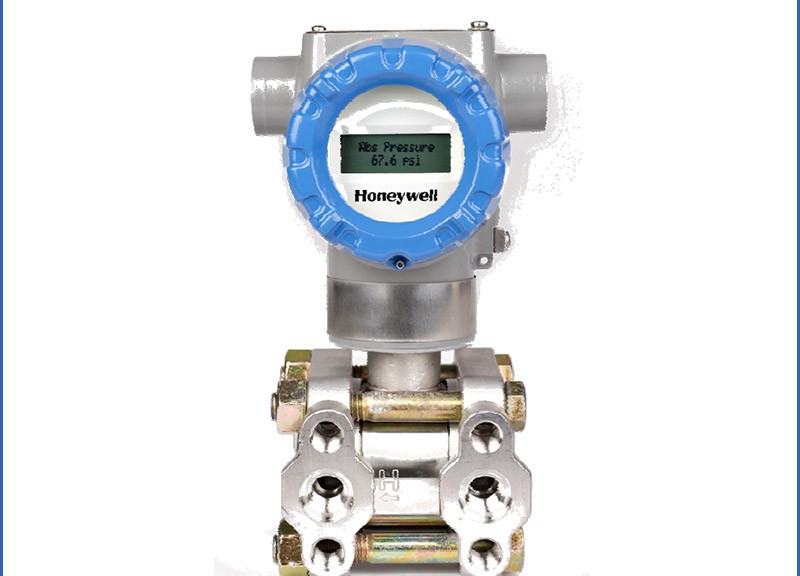

Level Transmitter

Level Transmitter Honeywell STF700 SmartLine Flange Mounted Level Transmitter easily meets the most demanding application needs for pressure measurement applications.

The ST 700 Flange Mount Pressure Transmitters are ideal for critical applications such as custody transfer of natural gas and energy and material balances, where accuracy and stability are of utmost importance. Five ranges of the transmitters from 400” H2O to 100 psi are available:

-

STF728 -400 to +400 inH2O -1000 to +1000 mbar

-

STF732 -100 to +100 psi -7.0 to +7.0 bar

-

STF72F -400 to +400 inH2O -1000 to +1000 mbar

-

STF73F -100 to +100 psi -7.0 to +7.0 bar

ST 700 transmitters offer the following compelling features:

-

Automatic static pressure and temperature compensation

-

Rangeability up to 100:1

-

Local display capabilities

-

External zero, span and configuration capability

-

Polarity-insensitive electrical connections

-

Comprehensive onboard diagnostic capabilities

-

Integral Dual Seal design based on ANSI/NFPA 70-202 and ANSI/ISA 12.27.0

-

Overpressure protection

-

Compliance with SIL 2/3 requirements

-

Modular design and 15-year warranty.

ST 700 Flange Mount Pressure Transmitters (ST 700) may be installed directly onto a tank flange and are offered with a variety of tank connections. Typical applications include high-accuracy level measurement in pressurized and unpressurized vessels in the chemical and hydrocarbon industries.